Understanding Pressure Reducing Valves A Key Component in Fluid Systems

Understanding Pressure Reducing Valves A Key Component in Fluid Systems

Gas Pressure Regulator Ensuring Safety and Efficiency in Gas Systems

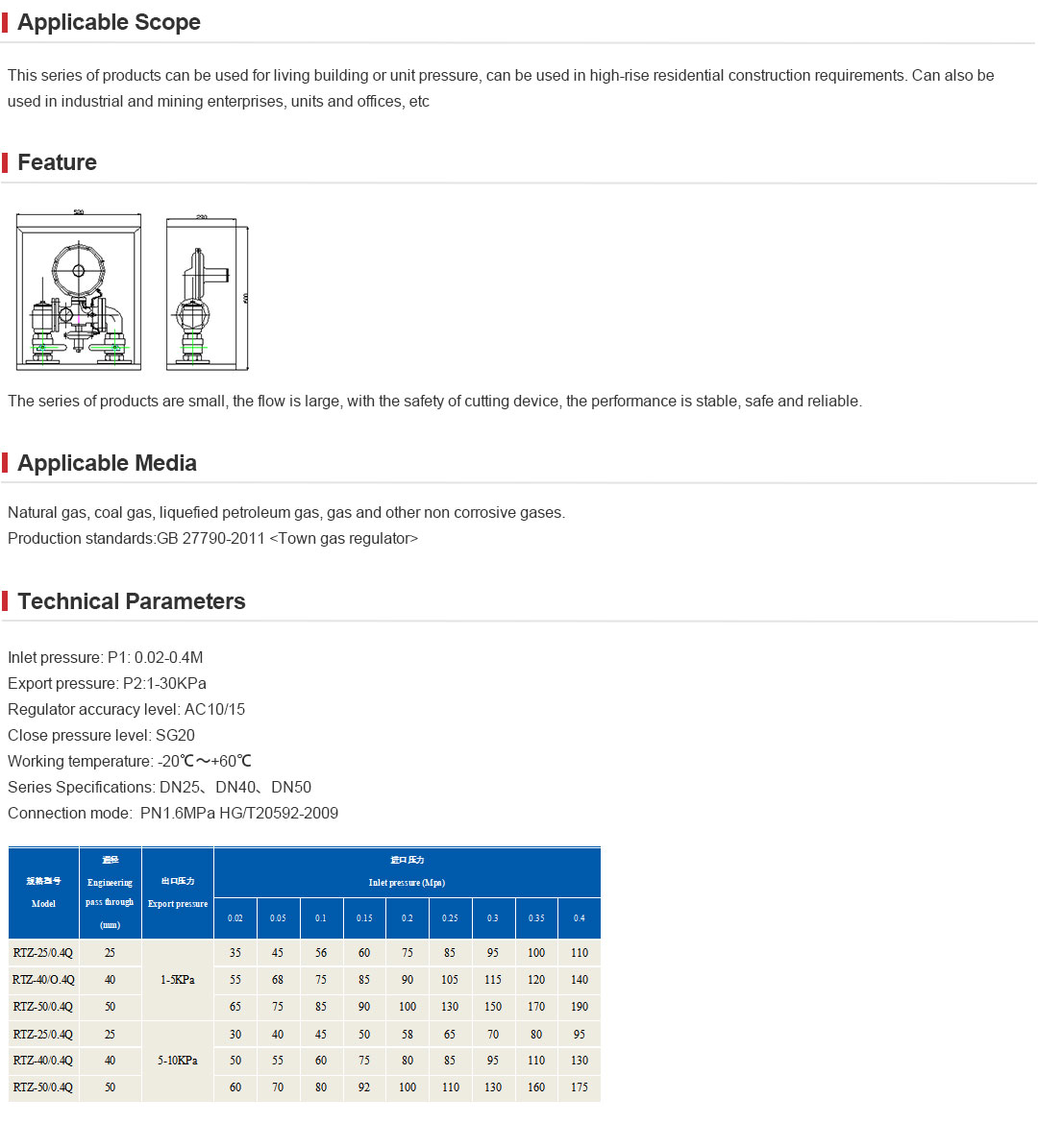

At the heart of a gas pressure reducing valve lies a simple yet effective mechanism. When high-pressure gas enters the valve, it encounters a diaphragm that responds to the pressure exerted on it. As the pressure increases, the diaphragm flexes, which adjusts the opening of the valve seat. This allows gas to flow into the downstream piping at a predetermined lower pressure, effectively reducing the incoming pressure to a safe and usable level.

A pressure regulating valve operates using a straightforward yet effective principle. It typically comprises a valve body, a spring-loaded diaphragm or piston, and an adjustment mechanism. The diaphragm reacts to the pressure change in the system. When the upstream pressure exceeds the pre-set level, the diaphragm moves to close off the valve gradually, reducing the flow. Conversely, if the pressure drops below the set threshold, the spring expands, allowing more fluid to flow through.

What is a Gas Pressure Regulator?

- Efficiency Regulators optimize the performance of gas-consuming equipment. By ensuring that devices receive the appropriate pressure, they operate more efficiently and have a longer service life.

Another important category is the gas-phase filter, which targets gaseous pollutants such as volatile organic compounds (VOCs), sulfur dioxide (SO₂), and nitrogen oxides (NOₓ). These substances pose significant health risks and contribute to the phenomena of smog and acid rain. Chemical sorbents, such as activated carbon, zeolites, and silica gels, are commonly used in gas-phase filters to adsorb or react with these harmful gases, thus preventing them from entering the atmosphere.

What is a Filter Separator?

Conclusion

- Regulatory Compliance Many industries are subject to strict regulations governing the safe handling of gas. Installing appropriate safety valves is often a legal requirement, helping businesses comply with safety standards set by organizations like OSHA and the EPA.

Understanding the Role of Commercial Regulators

In conclusion, natural gas regulators play a critical role in the safe and efficient use of natural gas. By regulating the pressure, they not only protect consumers and appliances but also contribute to the overall efficiency of gas distribution systems. Understanding the importance of these devices is essential for anyone who relies on natural gas for their energy needs.

4. Combination Valves These valves combine the functions of both relief and safety valves in one unit, providing versatility for different pressure management needs.

2. Efficiency Gas regulators contribute to the efficiency of gas appliances. When the gas is supplied at the correct pressure, appliances can operate more effectively, leading to reduced fuel consumption and lower operational costs. This is particularly significant in industrial settings, where even minor inefficiencies can result in substantial financial losses.

Gas coalescer plays a critical role in the oil and gas industry by efficiently separating liquid droplets from gas streams. This crucial piece of equipment helps to prevent equipment fouling, corrosion, and liquid carryover, ultimately ensuring the smooth operation of various processes.

In the water treatment industry, reducing stations are vital for controlling the pressure of water during processing. High-pressure water can lead to erosion of pipes and equipment, so reducing stations are employed to mitigate this risk. Moreover, they facilitate the efficient delivery of water to residential and industrial consumers, ensuring that water supply systems operate effectively.

The art installations adorning the walls, showcasing the works of local artists, add a dash of color and creativity to the space, reflecting the city's thriving arts scene The art installations adorning the walls, showcasing the works of local artists, add a dash of color and creativity to the space, reflecting the city's thriving arts scene

The art installations adorning the walls, showcasing the works of local artists, add a dash of color and creativity to the space, reflecting the city's thriving arts scene The art installations adorning the walls, showcasing the works of local artists, add a dash of color and creativity to the space, reflecting the city's thriving arts scene city gate station.

city gate station.The operation of a pressure reducing valve is straightforward yet effective. Typically, the valve consists of a diaphragm that responds to the changes in pressure. When the inlet pressure exceeds the set point, the diaphragm moves, causing the valve to open and allow some fluid to escape, thereby reducing the pressure downstream. Conversely, when the outlet pressure drops below the desired level, the diaphragm closes, restricting flow and allowing pressure to build up. This automatic adjustment ensures that the downstream pressure remains constant, regardless of fluctuations in the upstream pressure.

Conclusion

Pneumatic control valves also contribute to energy efficiency in production processes. Many modern valves are designed to minimize air consumption, which is particularly important given the rising costs of energy. Advanced technologies, such as proportional or servo-controlled valves, allow for more precise control of airflow, reducing waste and enhancing overall system efficiency.

- Relief Valves In the event of a malfunction, relief valves automatically vent excess pressure, minimizing the risk of explosions or other hazards.

The Role of Regulators in Modern Society

- Manufacturing In industrial settings, gas pressure reducers regulate the pressure of gases needed for welding, cutting, and other manufacturing processes.

Applications of Gas Pressure Reducers

- Immediate Replacement If a gas safety valve shows signs of malfunction or failure, it should be replaced immediately. Delaying replacement can lead to dangerous situations.

2. Automatic Gas Valves These valves operate automatically based on specific conditions, such as pressure or flow rate. They're commonly used in commercial and industrial settings, where safety and efficiency are paramount.

Looking to the future, the organization of the natural gas sector is likely to evolve in response to climate change policies and technological advancements. The integration of renewable energy sources and the development of hydrogen as a clean fuel alternative pose both challenges and opportunities. Natural gas may serve as a transitional fuel, aiding the shift to a low-carbon economy by providing a reliable backup for intermittent renewable energy sources.

The primary function of natural gas filters is to ensure that the gas delivered to end-users is clean and free from harmful substances. By using specialized filtration technologies, these systems are able to maintain the quality of natural gas, thereby enhancing its performance and reducing the likelihood of operational issues.

At their core, pressure reducing regulators operate on the principle of controlling the flow of fluids through a system. They accomplish this by utilizing a mechanism that adjusts the valve position based on the output pressure readings. Typically, a diaphragm is employed, which responds to the changes in output pressure. When the output pressure drops below a set threshold, the diaphragm moves to open the valve, allowing more fluid to flow through and thus increasing the pressure. Conversely, if the output pressure rises above the desired level, the diaphragm closes the valve to reduce flow and bring the pressure back within acceptable limits.

- Compliance with Standards Natural gas must meet specific quality standards before it can be distributed. Filter separators play a vital role in achieving compliance with regulatory requirements and industry standards.

What is Gasification?

The elasticated corners make it simple to tuck the sheet under the mattress, ensuring a neat and tidy appearance The elasticated corners make it simple to tuck the sheet under the mattress, ensuring a neat and tidy appearance

The elasticated corners make it simple to tuck the sheet under the mattress, ensuring a neat and tidy appearance The elasticated corners make it simple to tuck the sheet under the mattress, ensuring a neat and tidy appearance bedsheet with elastic all around. When it's time to change the sheets, simply pull the corners gently and the sheet will come off easily, saving you time and effort.

bedsheet with elastic all around. When it's time to change the sheets, simply pull the corners gently and the sheet will come off easily, saving you time and effort.

BTW, if you want to check out White Goose Down Pillows and Duvets, you can visit our collections page.

Why is European Flax Linen the Best in the World?

Pillowcases have many different kinds of closures, like buttons, ties, or envelopes. They may also have none at all. Depending on the purveyor, pillowcases are either sold separately or in pairs.

When researching bedding production, it pays to look for a reputable bedsheet manufacturer known for its expertise in producing high-quality bedding. Bedsheet manufacturers with a proven track record in producing flannel sheets are more likely to offer products that meet the highest standards.

In terms of fitted sheets vs. flat sheets there are distinctions in design, functionality, style, and the experience they offer.